Top Food-Safe Plastics: Customized Solutions from Leading Suppliers & Manufacturers

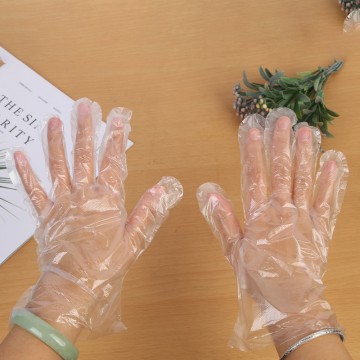

Quality and safety are essential when it comes to food packaging. Rizhao Wanjia International SCM Co., Ltd. offers a premium selection of plastic products that adhere to strict industry standards. Our range includes Food Bags, cling film, and disposable lunch boxes designed to keep your products fresh and secure. Partnering with us ensures access to factory-quality supplies from a reliable manufacturer. Our products, including ziplock and shopping bags, fulfill a variety of needs while prioritizing durability and convenience. Additionally, our disposable gloves and aprons ensure hygiene in food handling. With a focus on excellence, our advanced manufacturing techniques provide tailored plastic solutions for B2B clients. Choose Rizhao Wanjia for superior food packaging solutions today.

Expert Tips For Best Plastic For Food Manufacturer Where Innovation Meets 2025

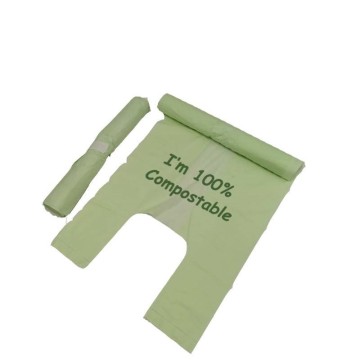

As the food manufacturing industry evolves, selecting the right plastic materials becomes crucial for maintaining quality, safety, and innovation. Understanding the unique properties of different plastics will allow manufacturers to make informed decisions that align with their production needs and sustainability goals. For instance, polyethylene (PE) and polypropylene (PP) are popular choices for food packaging due to their excellent barrier properties and resistance to moisture, making them ideal for preserving food freshness. In 2025, we anticipate a shift towards biodegradable and compostable plastics as regulatory pressure increases and consumer demand for sustainable options grows. Innovations in bioplastics developed from plant-based materials offer food manufacturers a pathway to reduce their environmental footprint without compromising on functionality. Moreover, incorporating smart technology into packaging—such as temperature indicators or freshness sensors—can enhance consumer trust and ensure food safety. Furthermore, the diverse range of plastic products—from durable garbage bags to versatile food storage options—presents multifaceted opportunities for efficiency in supply chains. By investing in advanced manufacturing techniques, like blow molding or injection molding, companies can tailor products to meet specific needs, enhancing customer satisfaction while contributing to a more sustainable future. Adapting to these trends will not only position manufacturers at the forefront of the industry but also ensure long-term profitability in a competitive global market.

Expert Tips For Best Plastic For Food Manufacturer Where Innovation Meets 2025

| Material Type | Key Properties | Food Safety Compliance | Sustainability Rating | Applications |

|---|---|---|---|---|

| PET (Polyethylene Terephthalate) | Lightweight, clear, recyclable | FDA approved | High | Bottles, containers |

| HDPE (High-Density Polyethylene) | Strong, durable, resistant to impact | FDA compliant | Medium | Milk jugs, detergent bottles |

| LDPE (Low-Density Polyethylene) | Flexible, resistant to acids | FDA approved | Low | Plastic bags, food wraps |

| PP (Polypropylene) | Heat resistant, durable | FDA compliant | Medium | Food containers, straws |

| PS (Polystyrene) | Good insulator, brittle | FDA approved | Low | Disposable cups, packaging |

Why China’s Best Plastic For Food Exceeds Industry Benchmarks Delivers Unmatched Quality

S

Samuel Lee

This product is top quality! The expertise of the after-sales support team made all the difference in my purchase journey.

17 June 2025

WITH

Zachary Ross

Incredible value for the quality! The after-sales service team was responsive and professional.

08 May 2025

M

Madison Perry

Superb product! The after-sales inquiry was handled with care and professionalism—very impressed!

19 June 2025

AND

Emma Moore

Outstanding product! The after-sales team was attentive and extremely knowledgeable.

26 May 2025

I

Isabella Martinez

Amazing craftsmanship! The after-sales personnel were very professional and helpful.

06 June 2025

S

Sophie Taylor

Outstanding product! The after-sales service was prompt and very well handled.

07 July 2025