Quality Disposable Plastic Gloves from Leading Manufacturer | Best Factory Direct Supply

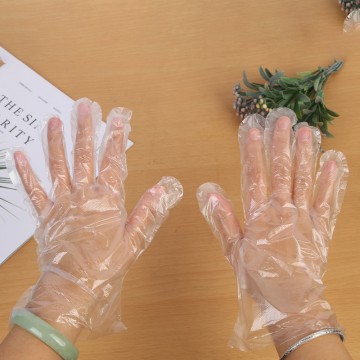

As a premier manufacturer of disposable gloves, our factory is dedicated to producing high-quality plastic gloves suitable for various applications, including food service, healthcare, and general use. We pride ourselves on our commitment to safety and sustainability, utilizing premium materials to ensure our gloves are both durable and comfortable. In addition to disposable gloves, our product range includes a variety of plastic bags, such as garbage bags, Food Bags, ziplock bags, and other disposable items like aprons and paper cups. With a focus on innovation and customer satisfaction, we are your trusted partner for quality products that meet your business needs. Contact us today for more information!

In-Depth Analysis of Methods Best Plastic Gloves Disposable Factory Factory For the Current Year

In the ever-evolving landscape of the disposable products industry, finding a reliable factory for high-quality plastic gloves is paramount for global buyers. As we delve into the current best practices and emerging trends of disposable glove manufacturing, it's crucial to consider factors such as material quality, production capacity, and compliance with health and safety standards. Recent advancements in manufacturing techniques have led to the development of more durable, versatile, and eco-friendly gloves, catering to various industries including food service, healthcare, and personal use. One of the key methods that factories are adopting is the implementation of advanced automation technologies. This not only enhances efficiency but also ensures consistent quality in every batch produced. Additionally, manufacturers are increasingly focusing on sustainable practices, such as using recycled materials and adopting energy-saving processes, which is becoming a significant deciding factor for environmentally-conscious buyers. It's also essential for factories to maintain transparency in their supply chain to foster trust and long-term relationships with global procurement teams. For those in search of disposable gloves, partnering with a factory that prioritizes innovation, sustainability, and quality assurance will yield significant benefits. The right factory should not only offer a diverse range of products tailored to meet specific needs but also guarantee compliance with international safety regulations. As you evaluate potential suppliers, consider their manufacturing capabilities, product certifications, and commitment to environmental responsibility. This thorough analysis will help ensure that you choose a factory that aligns with your business values and operational requirements in the competitive global market.

In-Depth Analysis of Methods Best Plastic Gloves Disposable Factory For the Current Year

| Method | Key Features | Benefits | Limitations | Application |

|---|---|---|---|---|

| Injection Molding | High-speed production, precision | Cost-effective for large volumes | High initial setup costs | Mass production of gloves |

| Blowing/Stretching | Flexible materials, light-weight | Comfortable fit | Lower durability | Food handling, light medical use |

| Thermoforming | Custom shapes, quick changes | Versatile designs | Limited to specific materials | Specialty applications |

| Coating Technology | Layering materials, enhanced grip | Enhanced performance | Increased manufacturing time | High-risk environments |

| Latex Dipping | Elasticity, comfortable feel | Good barrier protection | Allergic reactions in some users | Medical and industrial use |

Must-Choose Reasons Best Plastic Gloves Disposable Factory For the Current Year Factory-Direct Excellence

AND

Emily Thompson

The product quality exceeded my expectations. The attention to detail is impressive, and the after-sales service was extremely helpful.

17 May 2025

S

Samuel Lee

This product is top quality! The expertise of the after-sales support team made all the difference in my purchase journey.

17 June 2025

A

Ava Collins

Excellent product! The team handling after-sales was knowledgeable and patient—I felt valued as a customer.

29 June 2025

N

Noah Sanchez

Exceptional quality! The after-sales support team was articulate and very helpful in addressing all my concerns.

19 June 2025

H

Henry Hall

Incredible product! The after-sales support was not only quick but also very courteous.

11 June 2025

I

Isabella Martinez

Amazing craftsmanship! The after-sales personnel were very professional and helpful.

06 June 2025