Top Plastic Manufacturing Companies: Quality, Trust, and Reliability in Production

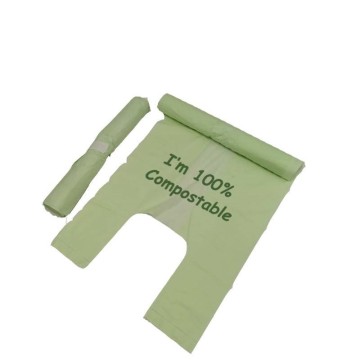

For top-tier plastic manufacturing solutions, our company delivers custom products designed to meet your specific requirements. Collaborating with trusted suppliers and factories, we offer a wide array of high-quality plastic items, including durable Garbage Bags, food-safe shopping bags, convenient ziplock bags, and cling film, suitable for various applications. Additionally, we manufacture an extensive range of disposable products such as gloves, aprons, lunch boxes, and paper cups, all aimed at enhancing convenience and efficiency. Serving industries like retail and food service, we uphold the highest quality standards while maintaining competitive pricing. Rizhao Wanjia International SCM Co., Ltd. is your trusted partner for all plastic packaging requirements, committed to delivering quality and ensuring customer satisfaction.

Best Practices For Best Plastic Manufacturing Manufacturer Supplies the World’s Top Brands Market Leader

In the ever-evolving world of plastic manufacturing, best practices are essential for organizations looking to supply top brands globally. A comprehensive range of products, including various types of plastic bags and disposable items, is critical to meet the diverse needs of different markets. From the environmentally conscious garbage bags to convenient food and shopping bags, the key lies in understanding customer requirements and maintaining high product quality. Manufacturers must adopt sustainable practices in production processes, ensuring compliance with international standards and regulations. Optimizing production efficiency while ensuring product safety and innovation is another hallmark of leading manufacturers. By leveraging advanced technologies and materials, companies can develop items such as ziplock bags and cling film that not only cater to practical uses but also appeal to eco-friendly consumers. Moreover, producing disposable products like gloves, aprons, and lunch boxes with recyclable materials showcases a commitment to sustainability, addressing the growing demand in the global market. Ultimately, collaboration and transparency in supply chain management are pivotal. Proactive communication with partners and considering customer feedback can lead to quicker adaptations in product design and functionality, strengthening relationships with key stakeholders. As global procurement efforts intensify, adhering to best practices in the plastic manufacturing industry will be crucial for delivering quality solutions that align with the world’s top brands.

Best Practices For Best Plastic Manufacturing Manufacturer Supplies the World’s Top Brands Market Leader

| Dimension | Description | Importance | Best Practice |

|---|---|---|---|

| Material Quality | Use of high-grade polymers | Affects durability and performance | Regularly test materials |

| Sustainability Practices | Use of recycled materials | Reduces environmental impact | Implement a recycling program |

| Process Efficiency | Optimizing production techniques | Increases output rates | Invest in training staff |

| Quality Control | Regular inspections of products | Ensures product reliability | Establish QA protocols |

| Customer Feedback | Listening to client needs | Improves product design | Conduct regular surveys |

Excellence in Best Plastic Manufacturing Manufacturer Stands Out Application

L

Linda Martinez

Excellent quality and design! The customer service team was proficient and made sure all my concerns were addressed swiftly.

23 May 2025

L

Logan Flores

Outstanding craftsmanship! The after-sales staff was incredibly professional and quick to resolve my concerns.

01 July 2025

A

Avery Bennett

Great quality and durability! The after-sales team was very professional, providing me with excellent support.

11 May 2025

THE

Oliver Perez

I’m very satisfied with this purchase! The quality is remarkable and the support was top-notch.

26 May 2025

C

Chloe Rivera

Superb product quality! The careful attention from the after-sales team was truly commendable.

08 June 2025

AND

Emma Moore

Outstanding product! The after-sales team was attentive and extremely knowledgeable.

26 May 2025