Top Quality Custom Disposable Plastic Manufacturers & Factories for Your Supply Needs

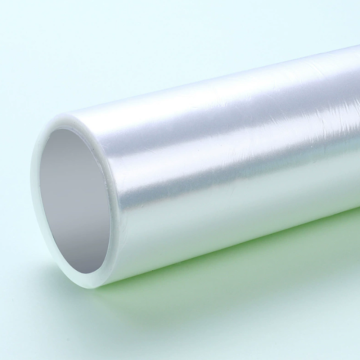

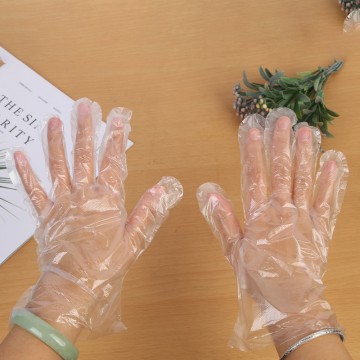

Find the finest custom disposable plastic products tailored to your specifications. Our factory excels in crafting a wide array of high-quality plastic items, including garbage bags, Food Bags, shopping bags, and ziplock bags. We also produce a variety of disposable items such as gloves, aprons, lunch boxes, and paper cups to meet all your needs.

Methods To Custom Disposable Plastic Manufacturers Is The Best Trusted by Pros

When it comes to sourcing high-quality disposable plastic products, finding a reliable manufacturer can make all the difference. Tailored solutions that meet specific business needs are crucial, especially in industries such as food service, retail, and hospitality. The best custom disposable plastic manufacturers offer a vast array of products, including garbage bags, food bags, shopping bags, ziplock bags, cling films, and various disposable items such as gloves, aprons, and lunch boxes. By partnering with these manufacturers, businesses can ensure they have access to innovative designs and materials that comply with safety and environmental regulations. The trustworthiness of a manufacturer is often determined by their industry experience, production capabilities, and commitment to quality. Pros in the field emphasize the importance of manufacturers who understand the complexities of different markets. These companies frequently invest in advanced technology and sustainable practices, ensuring that their products not only meet customer expectations but also adhere to environmental standards. By choosing a reputable manufacturer, buyers can achieve consistent quality, timely delivery, and the flexibility to customize products according to their requirements, ultimately enhancing operational efficiency and customer satisfaction. In conclusion, navigating the landscape of disposable plastic products requires a strategic approach to supplier selection. Engaging with trusted manufacturers who offer a comprehensive range of customizable options can greatly benefit businesses looking to enhance their product offerings and maintain a competitive edge. Making informed choices in sourcing can lead to stronger brand loyalty, reduced operational risks, and a positive impact on the environment, all while satisfying the diverse needs of global consumers.

Methods To Custom Disposable Plastic Manufacturers Is The Best Trusted by Pros

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Injection Molding | A process where plastic is melted and injected into a mold to create specific shapes. | High precision, fast production, and ability to create complex shapes. | High initial costs and limited to high volume production. |

| Blow Molding | A process used to create hollow plastic parts by inflating hot plastic in a mold. | Ideal for manufacturing bottles and containers, efficient material usage. | Less suitable for small production runs. |

| Thermoforming | A method where a plastic sheet is heated and shaped over a mold. | Low startup costs, quick turnaround for prototypes. | Limited complexity and thickness variations compared to injection molding. |

| Rotational Molding | Plastic powder is placed in a mold and rotated while heated to create parts. | Good for large, hollow products and even wall thickness. | Longer production cycles and limited detail on smaller parts. |

| 3D Printing | Additive manufacturing process to create parts layer by layer from a digital file. | Highly customizable, rapid prototyping, and low waste. | Slower production rates and potential strength limitations. |

Practical Methods To Custom Disposable Plastic Manufacturers Where Service Meets Innovation Factory

G

Grace Rivera

Outstanding quality! The after-sales support staff provided invaluable assistance, and they were very efficient.

15 June 2025

B

Benjamin Cooper

Superlative quality! The after-sales support staff were friendly and very competent in resolving my concerns.

09 June 2025

J

Jordan Murphy

Amazing product quality! The after-sales team was proactive and really cared about my experience.

13 June 2025

C

Chloe Lewis

Fantastic quality! The post-purchase service was very attentive and professional.

18 May 2025

M

Madeline Brooks

Outstanding craftsmanship! The professionalism of the after-sales team truly stands out.

04 June 2025

AND

Emma Lee

Remarkable quality! The post-purchase support team was efficient and incredibly helpful.

26 May 2025