Premium Custom Disposable Trash Bags from Leading Factory & Manufacturers

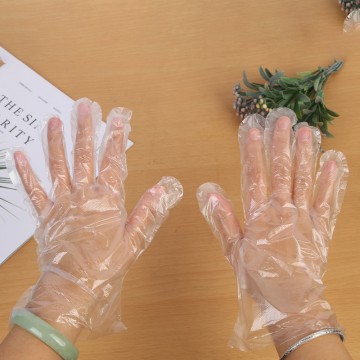

At Rizhao Wanjia International SCM Co., Ltd., we specialize in high-quality custom disposable trash bags and a variety of plastic products designed to meet your unique requirements. Our expertise extends to manufacturing garbage bags, Food Bags, shopping bags, and more, ensuring durability and reliability in every product. We also offer a diverse range of disposable items, including gloves, aprons, lunch boxes, and paper cups. By collaborating with trusted manufacturers, we aim to provide customizable solutions that enhance your brand while remaining affordable. Our experienced team is dedicated to working closely with clients to develop tailored specifications that align perfectly with your business needs, whether you are a small enterprise or a large corporation. We are committed to delivering top-quality products backed by exceptional service.

Key Methods For Custom Disposable Trash Bags Factory Is The Best Your Trusted OEM Partner

In today’s fast-paced world, businesses and consumers alike are increasingly relying on disposable products for convenience and hygiene. When it comes to sourcing high-quality custom disposable trash bags, finding a trustworthy OEM partner is paramount. Key methods for identifying the right factory can streamline your supply chain and enhance your product offerings. First, prioritize factories with a proven track record in producing a diverse range of plastic bags and disposable items. A reputable manufacturer should showcase their capability to deliver various specifications and styles, including not just garbage bags, but also food bags and shopping bags, ensuring that they cater to multiple market needs. This flexibility can significantly benefit global buyers who require adaptable solutions for their distinct target audiences. Second, evaluate the factory’s commitment to quality control and sustainability. A reliable partner invests in advanced production techniques and rigorous testing standards, ensuring that their products meet international safety and quality regulations. Additionally, as environmental concerns grow, partnering with a factory that emphasizes eco-friendly materials and processes can enhance your brand’s reputation and resonate with eco-conscious consumers. Ultimately, choosing the right OEM partner is about building a relationship that not only meets your immediate needs but also supports your long-term business goals.

Key Methods For Custom Disposable Trash Bags Factory Is The Best Your Trusted OEM Partner

| Method | Description | Advantages | Applications |

|---|---|---|---|

| Blown Film Extrusion | A process for producing thin film products from plastic resins by extruding the resin into a tube and inflating it. | High strength, uniform thickness, suitable for various applications. | Trash bags, agricultural films, and packaging materials. |

| Thermoforming | A manufacturing process where a plastic sheet is heated to a pliable forming temperature and molded. | Flexible design options, quick production times. | Custom-shaped bags and liners. |

| Injection Molding | A process in which melted plastic is injected into a mold to create different shapes. | High precision, ability to create complex shapes. | Manufacturing durable trash can liners and heavy-duty bags. |

| Bag Making Machines | Machines designed specifically to convert rolls of plastic film into finished bags. | Efficiency in production, customizable sizes and styles. | Retail and industrial trash bags of various sizes. |

How Chinese Manufacturers Custom Disposable Trash Bags Factory Global Reach Pioneers in the Field

AND

Emily Thompson

The product quality exceeded my expectations. The attention to detail is impressive, and the after-sales service was extremely helpful.

17 May 2025

M

Megan King

Fantastic item! The quality is remarkable, and the after-sales team was extremely helpful and courteous.

11 June 2025

S

Samuel Lee

This product is top quality! The expertise of the after-sales support team made all the difference in my purchase journey.

17 June 2025

S

Scarlett Kim

Impressive purchase! The product quality is amazing, and the after-sales service was professional and caring.

23 June 2025

M

Madeline Brooks

Outstanding craftsmanship! The professionalism of the after-sales team truly stands out.

04 June 2025

AND

Ethan Jackson

I’m very happy with this quality product! The after-sales support was genuinely professional.

28 May 2025