Top Factories & Suppliers for Quality Custom Plastic Gloves: Best Options Reviewed

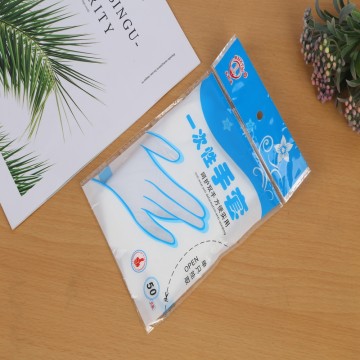

High-quality Custom Plastic Gloves are essential for various industries, including food service and healthcare. Our range of disposable gloves offers both comfort and durability, ensuring they withstand demanding environments. As a trusted supplier, we provide customizable options to suit your specific needs regarding size and style. In addition to gloves, our product line includes garbage bags and Food Bags, all designed with a commitment to quality. With Rizhao Wanjia International SCM Co., Ltd., you receive reliable products backed by a focus on client satisfaction for your operational needs.

10 tips Custom Plastic Gloves Custom Solutions, Products

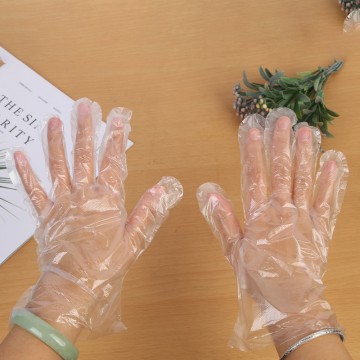

When it comes to various industries requiring hygiene and safety, custom plastic gloves have become essential. They are not only vital for health professionals but also for food service, cleaning, and numerous other applications. Here are ten tips to help you choose the right custom plastic glove solutions tailored to your specific needs. First, determine the materials that best suit your application. Options like vinyl, polyethylene, and latex offer different levels of comfort, barrier protection, and flexibility. For high-risk environments, opting for thicker, high-quality materials can provide enhanced durability. Next, consider the glove's fit and size. A poorly fitting glove can lead to discomfort and decreased dexterity, significantly impacting productivity. Many suppliers offer a range of sizes, so be sure to choose a supplier that can meet your specific requirements. Additionally, think about the intended use of the gloves. For example, food service professionals may require FDA-approved gloves that are safe for food contact, while medical facilities might prioritize gloves that meet specific industry standards for biohazard protection. Custom printing options on gloves can also be advantageous for branding and recognition in crowded environments. By focusing on these considerations, global procurement professionals can streamline their sourcing process and ensure they are choosing the ideal custom solutions for their operational needs.

10 Tips for Custom Plastic Gloves: Custom Solutions and Products

| Tip Number | Tip Description | Application Area | Material Type | Sizes Available |

|---|---|---|---|---|

| 1 | Choose the right thickness for durability. | Healthcare | Nitrile | S, M, L, XL |

| 2 | Consider powder-free options to prevent allergies. | Food Service | Vinyl | M, L |

| 3 | Opt for textured gloves for better grip. | Industrial | Latex | S, M, L |

| 4 | Ensure gloves are biodegradable for environment safety. | Healthcare | Biodegradable Nitrile | M, L |

| 5 | Make sure the gloves pass food safety certifications. | Food Preparation | Polyethylene | S, M, L, XL |

| 6 | Select color options for easy identification of use. | Medical | Nitrile | M, L |

| 7 | Look for gloves that provide tactile sensitivity. | Healthcare | Latex | M |

| 8 | Consider gloves with an extended cuff for safety. | Laboratory | Nitrile | M, L, XL |

| 9 | Evaluate glove performance under different temperatures. | Industrial | PVC | M, L |

| 10 | Assess the ease of putting on and taking off the gloves. | Healthcare | Latex | S, M, L |

Making Smart Choices Custom Plastic Gloves Products Industry Giant

AND

Ethan Parker

Top-tier quality! The after-sales personnel were friendly and provided insightful assistance with my queries.

19 May 2025

L

Liam Torres

High-quality product! The after-sales service was quick and very well handled by knowledgeable staff.

13 May 2025

J

Jordan Murphy

Amazing product quality! The after-sales team was proactive and really cared about my experience.

13 June 2025

S

Sophie Sanders

Excellent product! The after-sales personnel were friendly, professional, and efficient.

21 May 2025

H

Harper Cook

Impressive quality and design! The after-sales team was proactive and very professional.

06 June 2025

WITH

Zachary Robinson

Very impressed with the quality! Customer service was professional and genuinely helpful.

18 May 2025