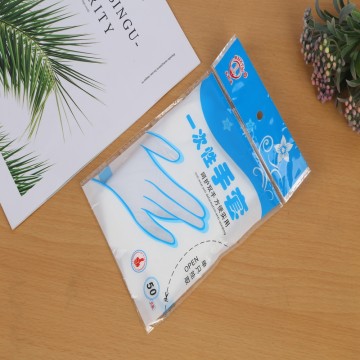

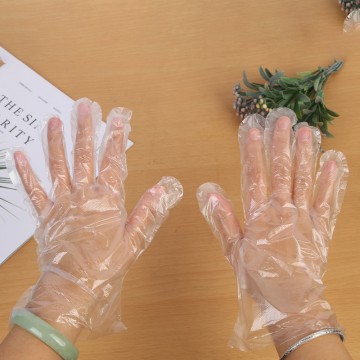

Top Custom Clear Plastic Gloves Manufacturer and Supplier for Quality Solutions

Reliable supplier for Custom Plastic Gloves and high-quality, clear disposable gloves designed for various applications including food handling and medical use. At Rizhao Wanjia International SCM Co., Ltd., we prioritize quality and comfort while ensuring dexterity in our products. Our diverse portfolio includes a wide range of plastic items such as Garbage Bags, shopping bags, ziplock bags, disposable aprons, lunch boxes, and paper cups. With a focus on flexibility and adaptation, we offer customizable options to meet the specific needs of our B2B clients. Partner with us for exceptional products and outstanding service, driven by our commitment to customer satisfaction and industry-leading standards.

Key Methods For Custom Plastic Gloves Clear Manufacturer Your Trusted OEM Partner Stands Out

When it comes to sourcing high-quality custom plastic gloves, partnering with a reliable OEM manufacturer can make all the difference. A trusted OEM partner not only delivers exceptional products but also ensures consistency, compliance, and customization to meet diverse needs. Key methods to identify a standout manufacturer include evaluating their product range, material quality, and manufacturing capabilities. It's essential to work with manufacturers who can accommodate various specifications and styles, offering solutions that align with your specific requirements. An ideal OEM partner should also demonstrate strong quality assurance processes, ensuring that every product meets safety and industry standards. Look for manufacturers with established certifications and a proven track record in producing a wide array of disposable products, including not just plastic gloves but also related items like aprons and food containers. Their capability to provide comprehensive solutions can significantly streamline your procurement process, allowing you to focus on growing your business while ensuring customer satisfaction with safe, reliable products. Furthermore, effective communication and strong customer support are vital aspects to consider. A responsive partner will be able to address your inquiries promptly, provide detailed product information, and collaborate closely throughout the production process. By prioritizing these elements, you can confidently select an OEM partner that not only fulfills your current needs but also supports your future growth in the competitive global market.

Key Methods For Custom Plastic Gloves Clear Manufacturer Your Trusted OEM Partner Stands Out

| Method | Description | Application | Benefits |

|---|---|---|---|

| Injection Molding | Process of injecting molten plastic into a mold | Production of high-volume glove manufacturing | High efficiency and precision |

| Blow Molding | Creating hollow plastic parts by inflating a heated plastic tube | Ideal for producing flexible gloves | Cost-effective for large quantities |

| Thermoforming | Heating plastic sheets and shaping them over molds | Used for specialty glove designs | Flexibility in designs and low production cost |

| Extrusion | Melting plastic and forcing it through a die | For continuous production of plastic sheets | High output and uniformity in products |

Reasons to Choose Custom Plastic Gloves Clear Manufacturer Factory-Direct Excellence Service

J

James Wilson

Top-notch quality! The support team was very responsive, making my experience seamless and enjoyable.

22 June 2025

M

Mason Stewart

Great quality! The after-sales support was quick, professional, and made my experience seamless.

12 May 2025

L

Lucas Price

I cannot recommend this product highly enough! The quality is superb and the after-sales team is exceptionally professional.

13 June 2025

C

Chris Nelson

Wonderful quality! The after-sales service was stellar, aiding me promptly with my inquiries.

15 June 2025

AND

Ethan Hill

Incredible craftsmanship! The after-sales support was quick to respond and very effective.

14 June 2025

AND

Emma Moore

Outstanding product! The after-sales team was attentive and extremely knowledgeable.

26 May 2025