Top Disposable Apron Manufacturers: Quality Products from Leading Factories

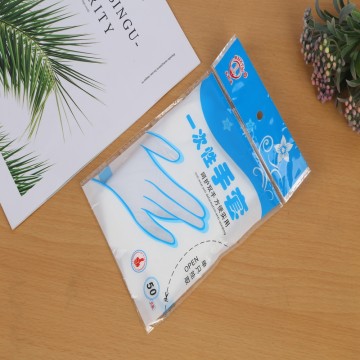

Rizhao Wanjia International SCM Co., Ltd. stands out as a leading manufacturer of disposable aprons, emphasizing quality and innovation. Our diverse range of high-quality disposable products is designed to meet various requirements, from food service to medical use, ensuring safety and hygiene without sacrificing comfort. Each apron provides comprehensive coverage and ease of use, with multiple specifications and styles available to suit different applications. As a trusted partner for bulk orders, we offer competitive pricing on all our disposable products. From Garbage Bags to gloves, our extensive selection caters to the comprehensive needs of your operations. Connect with us to elevate your business with our reliable solutions!

Best Practices For Disposable Apron Factories From Concept to Delivery For the Current Year

When it comes to sourcing disposable aprons, factories must adopt best practices that ensure efficiency and high-quality production, from concept to delivery. In the current year, global suppliers are increasingly focused on sustainability and compliance with international standards. Implementing an eco-friendly approach begins with sourcing materials that minimize environmental impact. Utilizing recyclable or biodegradable plastics can appeal to a growing segment of environmentally conscious consumers. Additionally, factories should invest in advanced manufacturing technologies that optimize production processes, reduce waste, and enhance product consistency. Collaboration and clear communication with international buyers are essential. Factories should focus on understanding specific client requirements, including design specifications and regulatory standards, to produce aprons that meet diverse market needs. Offering customizable options not only enhances product appeal but also strengthens relationships with buyers. Furthermore, maintaining a strong supply chain network enables timely delivery and responsiveness to fluctuating demand, which is particularly important in today's fast-paced market. Finally, rigorous quality control measures are critical throughout the production cycle. Regular inspections and adherence to quality standards help mitigate risks and ensure customers receive reliable products. By embracing these best practices, disposable apron factories can enhance their competitive edge in a global marketplace, solidifying partnerships with buyers who seek not just quality products, but also ethical and sustainable manufacturing solutions.

Best Practices For Disposable Apron Factories From Concept to Delivery For the Current Year

| Practice | Description | Importance | Frequency |

|---|---|---|---|

| Supplier Assessment | Evaluate suppliers based on quality, reliability, and compliance. | Ensures high-quality raw materials which affect final product. | Annually |

| Production Line Efficiency | Regularly assess and optimize production workflows. | Improves output and reduces waste. | Monthly |

| Employee Training | Implement regular training on equipment and safety. | Enhances safety and efficiency on the production floor. | Quarterly |

| Quality Control Checks | Systematically inspect products during and after production. | Ensures product meets specifications and prevents defects. | Every batch |

| Feedback Loop | Collect and analyze customer feedback to improve products. | Drives innovation and customer satisfaction. | Ongoing |

Champions of Disposable Apron Factories Your Trusted OEM Partner Guarantees Peak Performance

M

Michael Lee

This purchase has been a highlight! The quality is outstanding, and the professional service I received after purchase was commendable.

28 May 2025

K

Kevin Nelson

Absolutely satisfied with my purchase! The quality is outstanding and the after-sales service was prompt and very professional.

02 July 2025

N

Noah Sanchez

Exceptional quality! The after-sales support team was articulate and very helpful in addressing all my concerns.

19 June 2025

WITH

Zoe Hall

Great craftsmanship! The after-sales service exceeded my expectations with its professionalism and promptness.

03 July 2025

I

Isaiah Coleman

Absolutely love my order! The product quality is unmatched, and the after-sales support was incredibly helpful.

01 June 2025

L

Logan Smith

Wonderful craftsmanship! The way the after-sales team handled my questions was very professional.

22 June 2025