Top Custom Food Bag Plastic Manufacturers & Suppliers | Quality Solutions Available

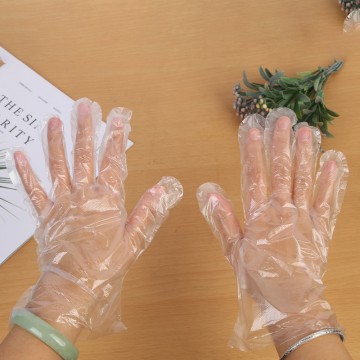

Our company specializes in manufacturing high-quality plastic bags to suit your business requirements. We provide a wide range of products, including Food Bags, garbage bags, shopping bags, ziplock bags, and cling films. Each product is designed for safety and convenience, ensuring an excellent experience for your customers.

10 Essential Tips For Food Bag Plastic Factories Sets the Industry Standard Your Trusted OEM Partner

In the evolving landscape of the packaging industry, food bag plastic factories are becoming a cornerstone of sustainable practices and innovative solutions. As global demand for reliable and safe food storage grows, manufacturers must adhere to strict quality standards while maintaining the flexibility to meet diverse customer needs. Here are ten essential tips that set the industry standard for food bag plastic factories, ensuring they remain the trusted OEM partner for global purchasers. Firstly, focus on high-quality materials that comply with food safety regulations. Utilizing BPA-free and food-grade plastics not only guarantees safety but also builds trust with consumers. Next, embracing innovative production processes can enhance efficiency and reduce waste, making operations more sustainable. Additionally, offering a diverse range of products, from ziplock bags to cling films, allows companies to cater to various markets, ensuring a broader customer base. Transparency in sourcing materials and production capabilities is also vital; it reassures clients about sustainability commitments and ethical practices. Moreover, fostering strong communication with clients throughout the design and manufacturing process is essential for understanding their specific requirements. Regular feedback loops and adjustments can lead to higher customer satisfaction. Lastly, investing in research and development to keep up with emerging trends, such as eco-friendly packaging solutions, will set your factory apart as a leader in the industry. By implementing these strategies, food bag plastic factories can establish themselves as the go-to OEM partner, meeting the ever-changing demands of global procurement efficiently and effectively.

10 Essential Tips For Food Bag Plastic Factories Sets the Industry Standard Your Trusted OEM Partner

| Tip | Description | Importance | Implementation |

|---|---|---|---|

| 1. Use Eco-Friendly Materials | Opt for biodegradable or recyclable materials to reduce environmental impact. | High | Source from suppliers of eco-friendly polymers. |

| 2. Quality Control Standards | Implement rigorous quality control checks throughout production. | Critical | Regular audits and sample testing of materials. |

| 3. Invest in Technology | Update machinery to improve efficiency and product quality. | High | Consider automation and Industry 4.0 solutions. |

| 4. Staff Training | Provide ongoing training for staff to ensure best practices. | High | Workshops and refresher courses regularly. |

| 5. Consumer Feedback | Listen to customer feedback to improve products. | Medium | Surveys and feedback forms after purchase. |

| 6. Compliance with Regulations | Stay up-to-date with industry regulations and standards. | Critical | Regular legal compliance checks. |

| 7. Sustainable Sourcing | Source raw materials from sustainable suppliers. | High | Evaluate suppliers based on sustainability practices. |

| 8. Efficient Logistics | Optimize logistics for timely delivery and reduced costs. | Medium | Employ logistics management software. |

| 9. Market Trends Analysis | Regularly analyze market trends to remain competitive. | Medium | Subscribe to industry reports and news. |

| 10. Strong Partnerships | Build strong relationships with suppliers and customers. | High | Engage in regular communication and collaborations. |

How To Find The Best Food Bag Plastic Factories Industry Giant Manufacturer

N

Natalie Baker

I love this product! The quality is exceptional, and the support team was very knowledgeable and courteous.

15 June 2025

A

Avery Bennett

Great quality and durability! The after-sales team was very professional, providing me with excellent support.

11 May 2025

WITH

Zoe Hall

Great craftsmanship! The after-sales service exceeded my expectations with its professionalism and promptness.

03 July 2025

C

Clara Young

Thrilled with this product! The after-sales service was prompt and very courteous.

21 June 2025

AND

Emma Moore

Outstanding product! The after-sales team was attentive and extremely knowledgeable.

26 May 2025

L

Logan Smith

Wonderful craftsmanship! The way the after-sales team handled my questions was very professional.

22 June 2025