Top Food Bag Plastic Manufacturers: Leading Supplier Factories for Quality Solutions

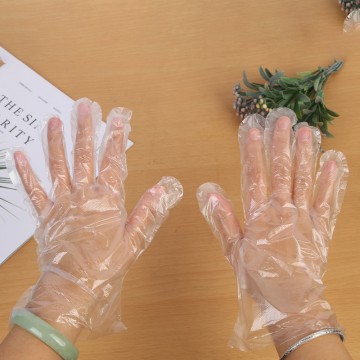

At our factory, we produce a wide variety of high-quality plastic bags to meet your specific needs. From durable garbage bags to convenient Food Bags and versatile ziplock bags, we have the right solution for you. We also offer an assortment of disposable products such as gloves, aprons, lunch boxes, and paper cups, all designed with quality and convenience in mind. As a leading supplier in the industry, we prioritize reliable and effective packaging solutions that comply with industry standards and enhance your brand. Trust Rizhao Wanjia International SCM Co., Ltd. for your plastic bag needs and experience exceptional quality and customer support. Contact us today for competitive pricing.

Must-Know Tips For Food Bag Plastic Manufacturers Dominates From Concept to Delivery

In the ever-evolving market of food packaging, understanding the nuances of plastic bag manufacturing is essential for global buyers. To ensure your supply chain runs smoothly from concept to delivery, consider these must-know tips that can enhance your purchasing decisions and strengthen partnerships with manufacturers. First and foremost, focus on the specifications and compliance standards required for food safety. Manufacturers should provide detailed information on the materials used, such as food-grade polyethylene, which ensures safety and durability. Additionally, understanding the variety of styles—ranging from ziplock bags for easy storage to high-strength garbage bags for waste management—can help you select the right products tailored to your needs. Quality control processes, such as material testing and adherence to local and international regulations, must be prioritized to mitigate any risks associated with food handling. Finally, maintaining effective communication with manufacturers is key. Regular updates on production timelines, potential delays, and customization options can significantly enhance collaboration. A commitment to sustainability can also be a deciding factor; inquire about eco-friendly materials and practices that align with your corporate social responsibility goals. By keeping these tips in mind, global buyers can navigate the complexities of food bag plastic manufacturing, ensuring successful transactions that meet consumer demands while prioritizing quality and safety.

Must-Know Tips For Food Bag Plastic Manufacturers Dominates From Concept to Delivery

| Tip | Description | Importance | Implementation Stage |

|---|---|---|---|

| Material Selection | Choose eco-friendly, durable materials for food safety. | High | Concept Phase |

| Regulatory Compliance | Ensure all products meet local and international food safety regulations. | Critical | Design Phase |

| Consumer Feedback | Incorporate user opinions and suggestions for product improvement. | Medium | Pre-Production Phase |

| Sustainability Practices | Integrate recycling and sustainability into production processes. | High | Manufacturing Phase |

| Quality Control | Implement rigorous testing to ensure product quality and safety. | Critical | Post-Production Phase |

| Supply Chain Management | Optimize logistics and supplier relationships for efficiency. | Medium | Delivery Phase |

Popular Food Bag Plastic Manufacturers Ahead of the Curve Service

J

Jessica Harris

High-quality product! The after-sales team went above and beyond to ensure I was satisfied with my purchase.

24 June 2025

A

Avery Bennett

Great quality and durability! The after-sales team was very professional, providing me with excellent support.

11 May 2025

H

Harper Cook

Impressive quality and design! The after-sales team was proactive and very professional.

06 June 2025

M

Matthew Adams

Absolutely fantastic quality! The professionalism of the after-sales team was highly commendable.

23 June 2025

AND

Ethan Jackson

I’m very happy with this quality product! The after-sales support was genuinely professional.

28 May 2025

AND

Emma Lee

Remarkable quality! The post-purchase support team was efficient and incredibly helpful.

26 May 2025