Custom Plastic Manufacturing: Trusted Suppliers & Tailored Solutions for All Needs

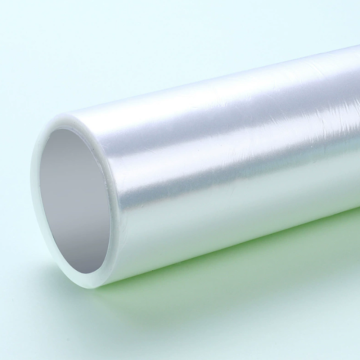

Our plastic manufacturing factory specializes in custom solutions tailored to your unique requirements. As a reliable manufacturer and supplier, we offer a wide range of plastic products, including garbage bags, Food Bags, and shopping bags, available in various specifications and styles. We also provide ziplock bags, cling film, and a variety of disposable items such as gloves, aprons, lunch boxes, and paper cups. Whether you represent a small business or a large corporation, we deliver high-quality plastic solutions that meet your needs. Our commitment to excellence ensures each product is crafted with precision and care. Partner with Rizhao Wanjia International SCM Co., Ltd. to benefit from our extensive expertise in plastic manufacturing. Contact us today to discuss your requirements and learn how we can supply top-tier plastic products for your business.

10 tips Plastic Manufacturing Factory Delivers Unmatched Quality For the Current Year

In the ever-evolving world of plastic manufacturing, maintaining high-quality standards is imperative for gaining a competitive edge. Here are ten essential tips that can help manufacturers ensure superior quality in their plastic products, catering to the increasing demands of global buyers. Focus on raw materials: Choosing the right raw materials is critical. High-quality plastics not only enhance durability but also ensure safety, especially for products like food bags and disposable utensils. Collaborating with reputable suppliers who offer certified materials is a smart strategy. Invest in advanced technology: Utilizing cutting-edge machinery and manufacturing techniques can significantly improve product quality. Automated processes reduce human error, while precise manufacturing minimizes inconsistencies in product specifications. Regular maintenance and updates of equipment also play a key role in sustaining operational excellence. Quality control processes: Implementing rigorous quality control checks at every stage of production is essential. From raw material inspection to final product testing, establishing a comprehensive quality assurance system ensures that only the best products reach the market. Additionally, being open to feedback from buyers can help identify areas for improvement. By adhering to these tips, plastic manufacturers can enhance their product quality and meet the rising expectations of global procurement professionals.

10 Tips Plastic Manufacturing Factory Delivers Unmatched Quality For the Current Year

| Tip Number | Quality Focus Area | Description | Expected Outcome |

|---|---|---|---|

| 1 | Raw Material Quality | Ensure all raw materials meet industry standards. | Enhanced product durability. |

| 2 | Employee Training | Provide regular training to staff on best practices. | Increased efficiency and reduced errors. |

| 3 | Machinery Maintenance | Implement a routine maintenance schedule for equipment. | Consistent product quality and less downtime. |

| 4 | Quality Control Testing | Establish stringent quality control processes. | Early detection of defects. |

| 5 | Supplier Collaboration | Work closely with suppliers to ensure material quality. | Consistent supply of quality materials. |

| 6 | Lean Manufacturing | Adopt lean principles to reduce waste. | Higher efficiency and lower operational costs. |

| 7 | Feedback Loops | Implement a system for customer feedback and improvements. | Improved products and customer satisfaction. |

| 8 | Sustainability Practices | Incorporate sustainable materials and processes. | Better brand image and eco-friendliness. |

| 9 | Technology Integration | Utilize advanced technology for production and tracking. | Streamlined operations and data accuracy. |

| 10 | Compliance and Standards | Stay updated with industry regulations and standards. | Reduction in compliance issues and penalties. |

How Chinese Manufacturers Plastic Manufacturing Factory Where Innovation Meets 2025 Dominates

D

David Brown

The craftsmanship is remarkable. What stood out most was the dedicated after-sales support that truly cares about customer satisfaction.

28 June 2025

L

Lily Rivera

I’m thoroughly impressed by the quality and the professional after-sales service I received. Truly commendable!

04 June 2025

G

Grace Rivera

Outstanding quality! The after-sales support staff provided invaluable assistance, and they were very efficient.

15 June 2025

C

Clara Young

Thrilled with this product! The after-sales service was prompt and very courteous.

21 June 2025

S

Sophia Martinez

Great quality! The after-sales team was quick to address my queries in a professional manner.

05 July 2025

G

Grace Hill

Super high quality! The after-sales team made the entire process seamless and enjoyable.

24 June 2025